What’s the WPC material?

Wood plastic composites(WPCs) normally are about 65:25 mixtures of small wood particles and thermoplastic polymers ( But our items include more than 40% HDPE – high quality ). Plastic and wood each have their own strengths in producing composite material. Plastic augments the durability and stability of the wood, whereas wood offers a look and feel to plastic that had always been missing in other older formulations. These wood-plastic composites mix fine wood particles with biodegradable, renewable, recycled, or virgin plastic materials to make smooth, firm, planks for easy handling and additional processing; converting them into composite decking boards.

Fully automatic German import production line

With a professional engineering and management team, our extensive experience ensures the best composite deck boards for you

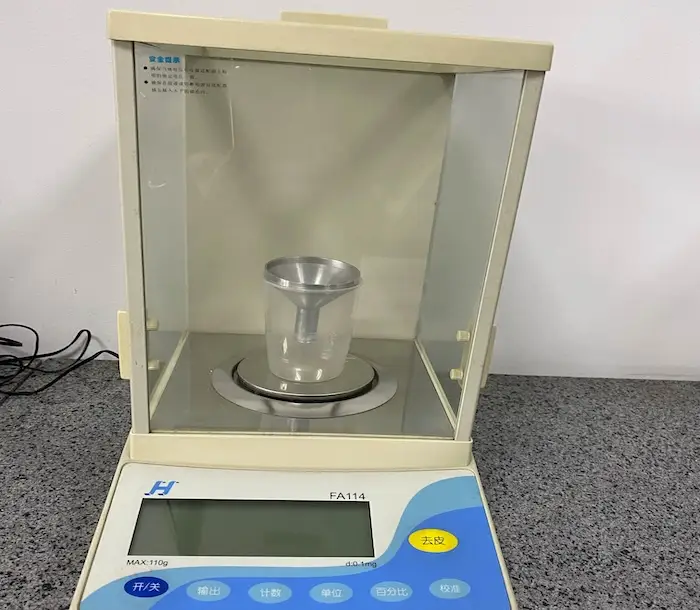

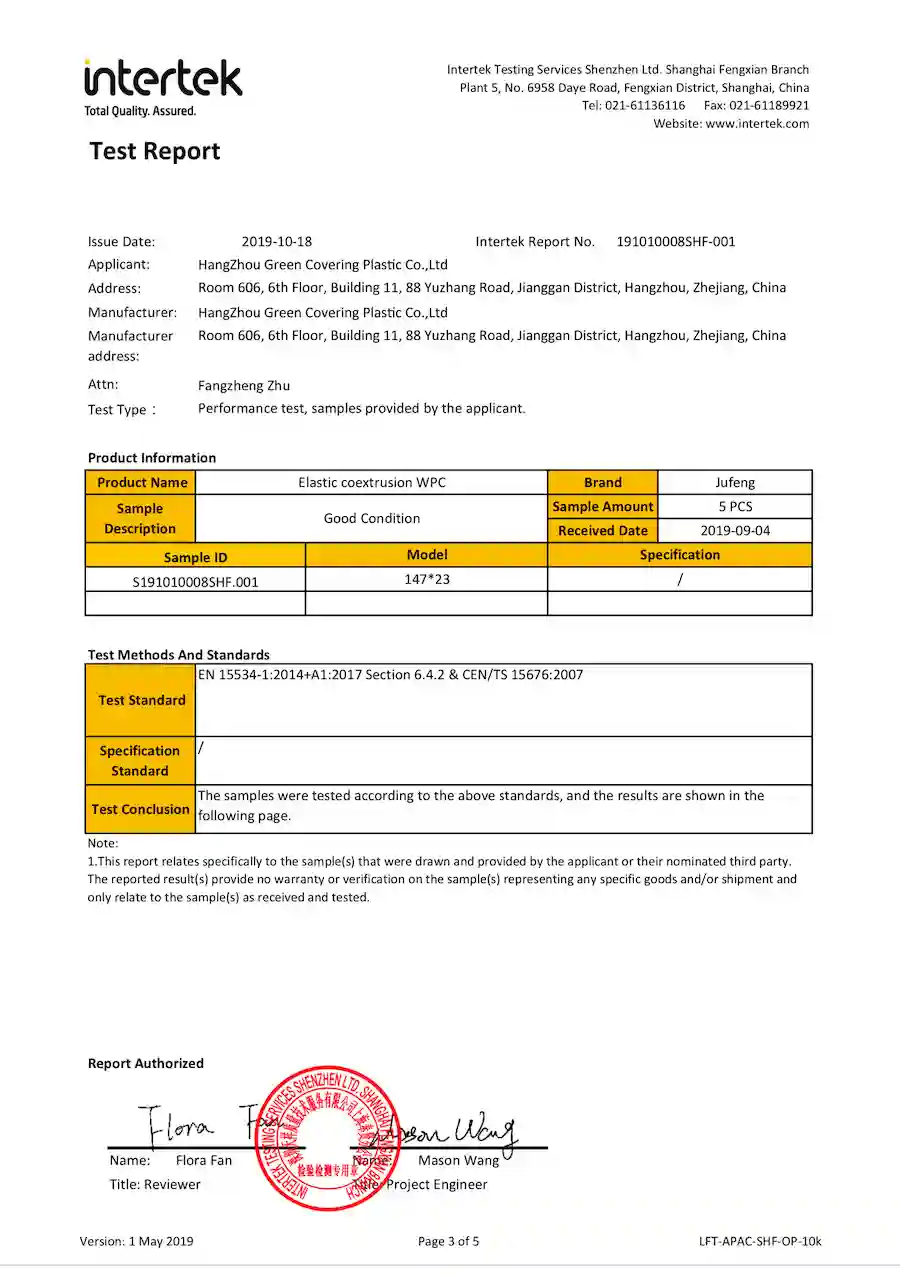

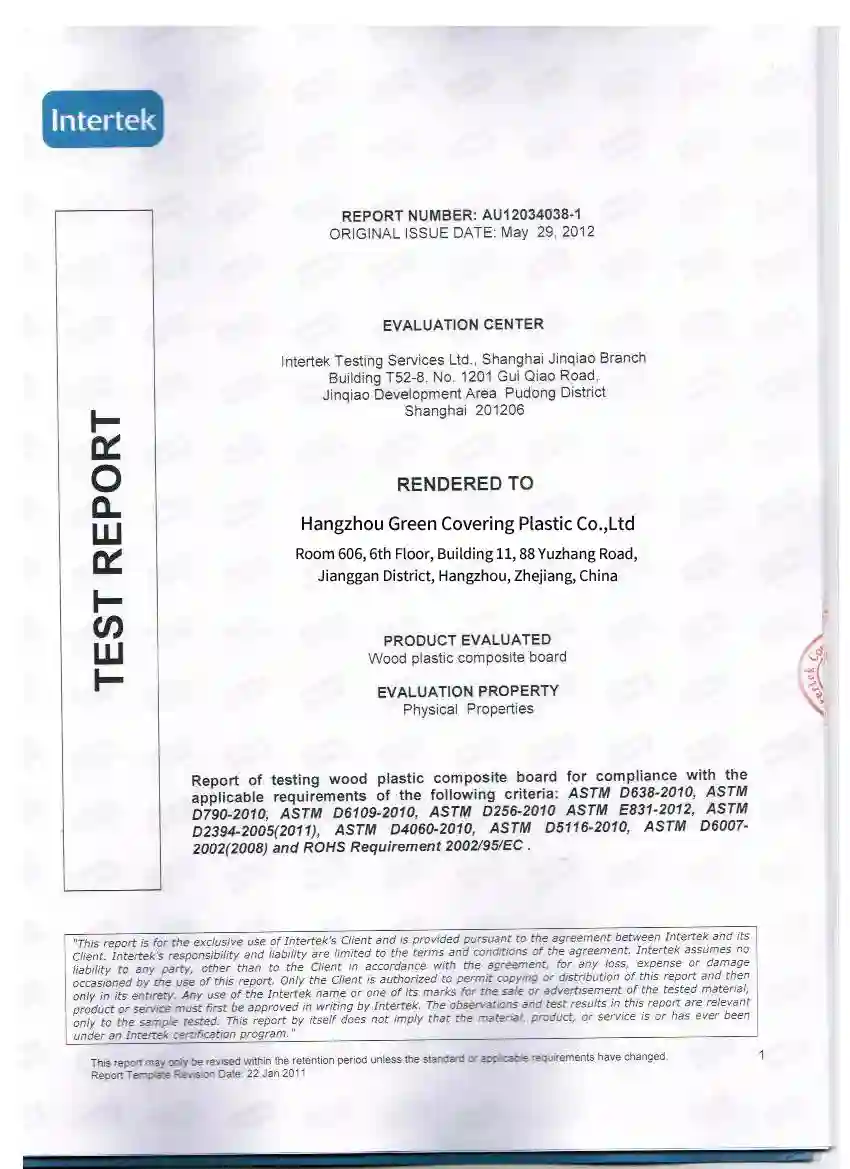

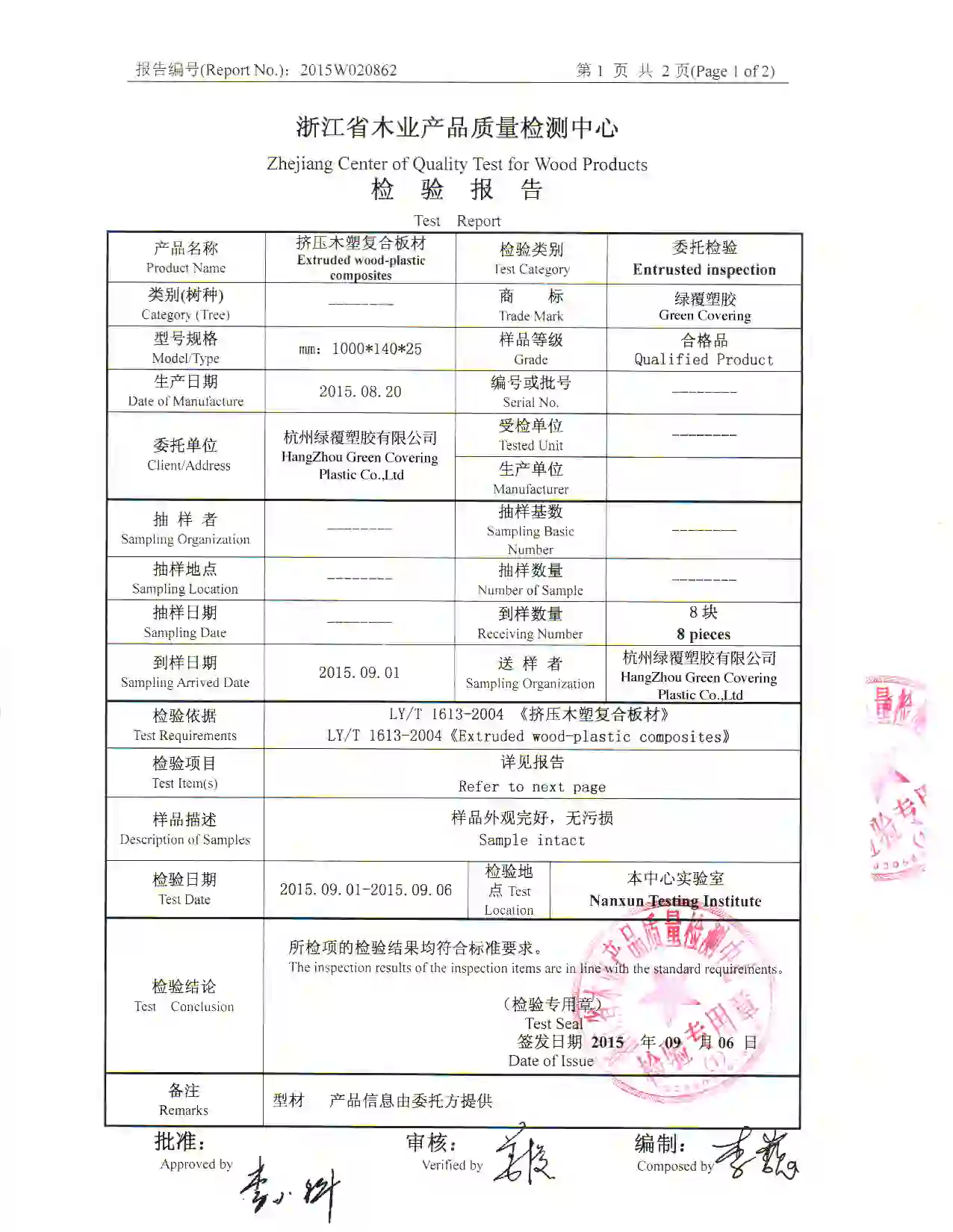

Performance Test

we will conduct performance testing on our WPC items before and after the formal production, and data such as impact strength bending failure load, Shore hardness and density can be obtained through different instruments to consider whether each batch of products meet our requirements to ensure that each batch of goods is of high quality.

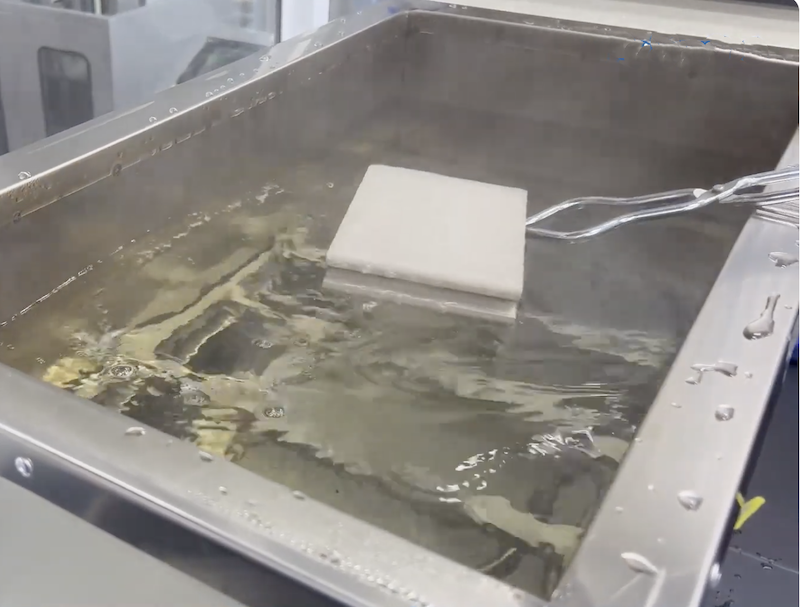

Boiling Test

After the product meets the requirements of the first two tests, we carry out the third test, where the decking boards are boiled at a high temperature of 100 degrees Celsius for more than 48 hours without interruption. We have detailed weight and size before cooking, after cooking for more than 48 hours, take out the floor to cool, and then observe whether the surface cracks, etc. and then compare the size and weight, you can get the water absorption expansion rate and the performance of the floor under bad conditions.

Aging Test

Put different batches of composite board into the test instrument in turn. The instrument will simulate different UV intensities of the sun, and after long-term intensive irradiation, compare the color of the product and the aging degree of the surface after strong sunlight irradiation, to judge whether the product meets the standard.

Wood Composite Toolshed

The tool room made of WPC is not only easy to move, but also can be disassembled. Composed of wood plastic posts, composite decking boards, slivers, etc., connected together with hardware accessories, stable enough to resist wind and rain. Our composite toolshed has been configured with all the necessary accessories, when you purchase back can be easily installed and combined, you can choose your favorite color according to your requirements, the color of the wpc part can be customized, compared with wood made, wpc is more waterproof, UV resistant, and do not worry about insects, mildew and other problems in the outdoor. If you would like a small warehouse or tool room, contact us for more detailed sizes and prices.

Composite Bench

WPC materials are widely used, not only can be used as decking floor, wall panels, fences, handrails, etc., but also can be made into benches in parks or other outdoor scenes according to different size requirements. Our wpc uses high-density wood flour and new materials of HDPE, so the product has good stability, strong UV resistance, good bending resistance, more waterproof, low expansion rate. So even if it is made of outdoor tables and chairs, it does not affect its service life, a variety of sizes of composite decking boards can be customized according to customer requirements of different designs of tables and chairs, any questions can contact us at any time.

Using the finest materials ensures our products’ superior and stable quality

High Quality Virgin HDPE

High quality HDPE can make WPC have good tensile strength and impact resistance. With excellent anti-ultraviolet ability, high-quality HDPE can make WPC(composite decking boards) better waterproof, reduce the rot, mildew and expansion caused by wet environment or water penetration. High-quality HDPE is more environmentally friendly, in line with the standard of green and sustainable development, and does not contain harmful substances.Low quality HDPE may contain impurities or harmful substances that affect the environmental characteristics and safety of the product.

High Density Wood Powder

In WPC, the choice of wood powder directly affects the structure, performance and appearance of the product. Wood flour acts as a reinforcing material in WPC( wood plastic composite), and high-quality wood flour can be evenly distributed in the plastic matrix to improve the bending resistance of the product, while low-quality wood flour may lead to the internal structure of the product being unstable and easy to crack or fracture. The high quality wood powder is fully dried and filtered, and the water absorption is strong without problems such as expansion and warping.

High Purity Compatibilizers and additives

In the production process of WPC (wood plastic composite), the quality and proportion of compatibilizers and additives have a crucial impact on the performance and quality of the product. The main role of compatibilizers is to enhance the adhesion between plastic and wood powder, while various additives can optimize other properties of composite decking boards, high-quality compatibilizers can improve the adhesion of wood powder and HDPE, to ensure the strength and uniformity of the material, and additives can improve the anti-aging, anti-mold,,etc…