Why choose SPC flooring?

SPC flooring(stone plastic composite) is mainly made of PVC and calcium powder extrusion molding floor, rigid core SPC flooring substrate layer after special treatment and strict ratio has good stability, but because of temperature and humidity and obvious expansion or contraction. The main component is stone plastic, so it has excellent waterproof performance, not like wood flooring because of moisture erosion and mold, very suitable for kitchen, bathroom and other wet places. The installation is a locking installation, without the use of glue, with a certain fireproof performance, the surface of the wear-resistant layer is not only wear-resistant and easy to clean and not easy to scratch, plus IXPE mute pad at the bottom, there is a certain sound absorption effect, reduce the transmission of footsteps and other noise.

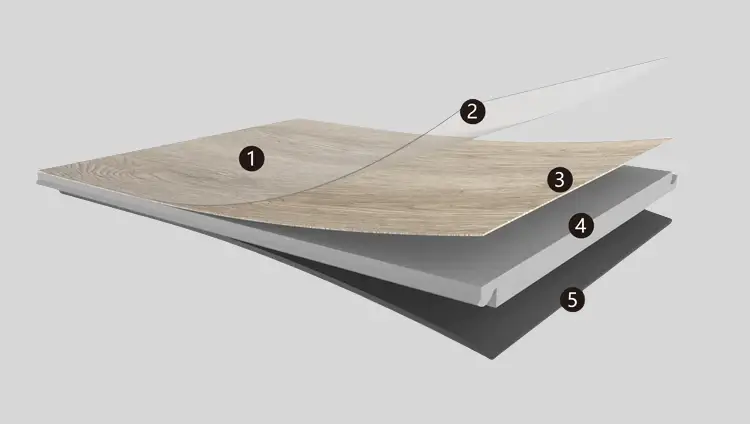

SPC Flooring Structure

1.UV coating (double)

2.Wearlayer (0.1-0.7mm)

3. PVC film layer (colors)

4.Special rigid core(waterproof)

5.Attached pad (IXPE,EVA,CORK)

EIR design SPC flooring

EIR (embossed in register) is based on the pattern of logs, making decorative paper and relief pressed steel plate with the same texture, using a hot press to press the relief steel plate and pvc color film on the surface of spc rigid core, so that the embossed and PVC color film wood grain has been, the overall visual feeling will be lively. Visually closer to solid wood flooring.

Herringbone spelling spc flooring

Herringbone SPC flooring looks full of personality, as long as you choose the right color and size, no matter what style or how much space can be easily handled. The diagonal spelling of long wooden strips and the interleaving of herringbone spelling can bring eye-catching effect and creativity to the space. The herringbone spelling of the floor Mosaic method is atmospheric and classical, which can greatly add points to the overall texture

Production process of SPC flooring and quality control

Vinyl Composite Floor Tiles Factory

Vinyl composite floor tiles is also a kind of SPC flooring, the material is the same, but on the decorative paper (PVC color film), we choose a stone design, different grain texture, so that the SPC floor is closer to the ceramic tile, but it is lighter than the tile, and non-slip.

FAQ – SPC flooring

Performance test of SPC flooring in extreme environment

Performance test of SPC floor in extreme environment

All SPC flooring need to be put into our testing equipment for more than 24 hours before formal mass production to simulate the shrinkage rate and water absorption rate of the flooring in a high temperature environment to ensure that there will be no quality problems when used in different regions and countries, and to ensure the service life.