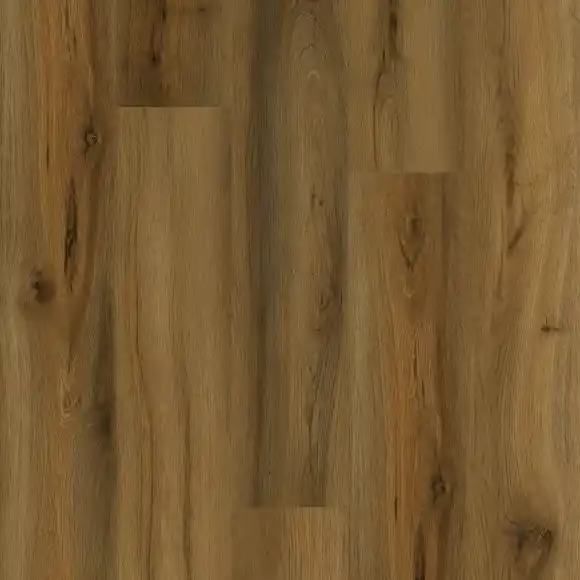

What’s glue down vinyl plank flooring ?

Glue down vinyl plank flooring(dry back vinyl flooring) is also a type of vinyl flooring, but with different installation methods, including glue down and click system flooring. When installing glue down vinyl plank flooring, a layer of glue is first applied to the floorboards, then they are laid on the ground. Because their thickness is generally between 2mm and 3mm, they can be cut and pieced together freely.

If you want to try DIY, this type of flooring is very suitable; it can be laid not only on the ground but also installed on walls. Glue-down flooring is made by hot-pressing resin powder and calcium carbonate powder. Different grades of resin powder greatly affect the stability of the glue-down flooring. Green Covering uses only 100% new resin powder materials.

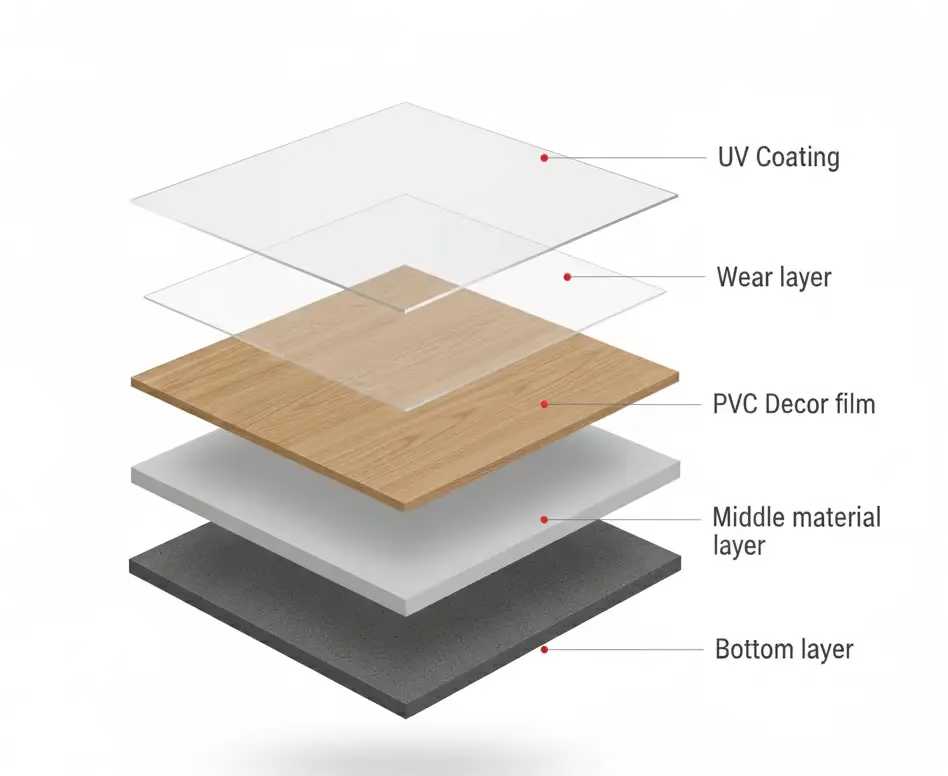

Glue down vinyl plank flooring structure

1.UV Coating:We use high-end German imported UV paint, which is fade-resistant, completely invisible and transparent, and does not affect the clarity of the color film.

2.Wear Layer: Tolerance controlled within 0.02mm, made of high-purity resin powder, with a light transmittance of over 98%.

3.Color Film Layer: High-precision 4K color printing, large printing rollers, low repeatability, and color error of reorders does not exceed 3%.

4.Intermediate Layer: Made of the same material as the base layer, incorporating glass fiber for higher strength and greater tensile strength.

5.Bottom Layer: Specific texture increases the contact area of the adhesive, and the designed density and shrinkage coefficient provide sufficient tensile strength to support the high-strength wear-resistant layer.

OUR PRODUCT

Product By Features

Our Glue down vinyl plank flooring offers over 3,000 colors and dozens of wood species. Whether you need to select or match colors, we can provide multiple options in the shortest time. All colors are delicate and realistic, and the color film printing offers rich hues.

OUR PRODUCT

Glue down vinyl plank flooring advantages

Why choose our glue down vinyl flooring?

Green Covering’s glue down vinyl flooring comes in thicknesses of 2mm, 2.5mm, and 3mm. Our 2.5mm thickness can already support a 0.7mm wear layer.

This means the subfloor must have extremely high load-bearing capacity to support the 0.7mm abrasion layer; otherwise, the wear layer is prone to peeling, and the ends of the flooring are likely to warp.

Furthermore, choosing a 0.5mm or 0.7mm thick abrasion layer likely indicates commercial use in high-traffic areas. Dimensional stability is crucial to prevent expansion joints or warping after a period of use. Therefore, we not only adjust the subfloor composition according to the abrasion layer thickness but also add fiberglass to enhance the flooring’s strength. As a result, our glue down vinyl flooring is more dimensionally stable and will not deform, warp, or crack over long-term use. All raw materials are sourced exclusively from reputable manufacturers, ensuring stable and guaranteed quality for every order.

Glue down vinyl flooring VS Click vinyl flooring

The adhesive used in glue-down vinyl plank flooring is crucial. Using high-quality adhesive ensures a very secure and durable bond, making it suitable for high-traffic areas.

However, glue-down vinyl plank flooring is slightly more difficult to install and has a higher installation cost than Click flooring, although the flooring itself is less expensive. Generally, glue-down vinyl plank flooring doesn’t include an underlayment, so the feel underfoot isn’t as comfortable as Click flooring. However, because it lacks a locking system, there is less waste.

OUR PRODUCT

Green Covering Factory Feature

Why we sold out 100,0000+boxes glue down vinyl plank per year?

Plasticizer

In the production of glue down vinyl flooring, besides PVC resin powder and calcium carbonate powder, additives are also crucial. Good additives allow the components to blend together better. Many factories use cheaper additives to save costs. For example, plasticizers are extremely important in PVC flooring production.We use medical-grade organic DOTP, while DOP or DINP are much cheaper. However, these two plasticizers contain phthalates, which are banned in Europe and America. They are not only carcinogenic but also easily volatilize, affecting the stability of the flooring.

PVC Resin Powder

To reduce costs, many factories mix recycled materials into their flooring. Our resin powder, however, is sourced from a top domestic supplier of ethylene-based PVC resin powder.Therefore, even in cold winter temperatures, our flooring remains flexible and won’t easily break. If recycled materials, such as old electrical wire insulation or conduit, are used, the flooring will contain impurities. Recycled plastic also lacks flexibility, making the flooring more prone to breakage. Furthermore, flooring made from brand-new PVC material will allow light to pass through when a flashlight is shone on it.

What our customers are saying

I’ve been sourcing from Green Covering Factory for over a year now, and their glue down vinyl planks have become my go-to for high-traffic commercial projects. What sets their product apart is the dimensional stability; even in areas with significant temperature fluctuations, we see zero gapping or peaking. The backing is perfectly textured to bond with the adhesive, ensuring a flat, permanent fit. My clients love the realistic embossed-in-register (EIR) finish—it gives the look of authentic hardwood without the maintenance headaches. Highly recommended for pros who need reliability.

When working on residential multi-family projects, I need a balance of aesthetics and cost-effectiveness. Green Covering Factory nailed it with their latest glue down collection. The color consistency across batches is impressive, which is rare in this industry. We recently installed their ‘Natural Oak’ series in a 50-unit complex; the planks are thin enough to make transitions easy but have a heavy-duty wear layer that handles scratches from pets and furniture beautifully. It’s rare to find a factory that prioritizes both the chemical safety (low VOCs) and the high-end design trends

We switched to Green Covering Factory for all our flooring replacements three seasons ago. Their glue down vinyl is a game changer for rental properties. Unlike click-lock systems, if a single plank gets damaged by a tenant, my maintenance crew can easily swap out just that one piece without tearing up the whole room. The water resistance is 100%—we’ve had minor leaks that would have ruined laminate, but this vinyl wiped clean and stayed intact. Dealing directly with the factory has also significantly cut our overhead costs while improving the ‘luxury feel’ of our units

OUR PRODUCT

Some about glue down vinyl plank flooring you may interested

1.Are dry back vinyl flooring prone to warping?

The reason dry back vinyl flooring (glue down vinyl plank flooring) is prone to warping is that some factories cut corners on the middle layer, using inferior materials, resulting in insufficient tension. The base layer also lacks quality. This is more likely to occur when the wear layer is thick. Green Covering Factory’s glue-down flooring uses the same proportions and materials for both the middle and base layers, including high-quality PVC resin powder. Glass fiber is added to the middle layer as needed, ensuring consistent tension across the top, middle, and bottom layers. This mutual restraint prevents the flooring from delaminating and warping.

2.Are Glue down vinyl flooring prone to shrinkage?

Our Annealing process is excellent, fully releasing stress.Annealing is crucial for preventing shrinkage in the later stages of flooring production. Our annealing line exceeds 50 meters, undergoing multiple temperature cooling stages to release the temperature and internal stress accumulated during hot pressing.

After thorough temperature reduction on the annealing line, the glue down vinyl flooring is placed in a constant-temperature chamber for 48 hours to ensure complete release of residual stress. Our flooring is then baked in an 80-degree oven for 6 hours. The final shrinkage rate is only 0.03%, significantly higher than that of smaller factories.

3.What’s the difference between glue-down vinyl flooring and vinyl sheet flooring?

Glue down vinyl plank flooring comes in sheets, which can be cut to 6″x48″ or 7″x48″ according to customer requirements. It’s typically wood-grain cut into strips, but carpet and stone patterns are also available. It’s usually square or 12″x24″ in size. Vinyl sheet flooring, on the other hand, comes in rolls and is commonly used in micro-foamed vinyl flooring for kindergartens or functional flooring for hospitals requiring antibacterial properties.

4.Can you guarantee that the color of each batch will be the same?

We keep copies of the raw materials and color film for every order, and we also have a raw material locking mechanism for different customers, such as supermarkets, to control the color error within 3% for each batch.

5.Will glue-down vinyl plank flooring look cheap and have a plastic-like surface?

We use large rollers, ensuring that no two planks are the same (up to 8-10 planks). This gives the vinyl flooring a random feel, which is why many of our orders are for high-end hotels. Using paint beveling or synchronized pattern matching, the texture and embossing follow the wood grain, making it impossible to distinguish between real wood and vinyl to the touch, thus satisfying the designer’s desire for a sophisticated look.

6.If I have many apartments that need renovation, would this flooring be suitable?

We understand that many apartment flooring suppliers are most concerned about floor damage leading to temporary closures for maintenance and lost rental income.

Our glue down vinyl plank flooring uses high-quality raw materials and over 25 years of experience, combined with a sufficiently thick 0.3mm-0.5mm wear layer, guaranteeing 5-7 years of high-frequency rental without quality issues. While our prices aren’t the cheapest, we can guarantee 0% peace of mind regarding quality. Our goal is long-term business; our clients’ interests are aligned with ours. A win-win business is the only way to last.

7.Is glue-down vinyl plank flooring suitable for supermarkets?

Our glue down vinyl plank flooring is perfectly suitable for commercial spaces. Large supermarkets have shelves and shopping carts every day, and the flooring can easily be damaged by accident. Glue down vinyl plank flooring has no interlocking mechanism; it’s laid flat with adhesive. Furthermore, our dry back vinyl flooring uses a mature hot-pressing process and has passed heavy-duty roller tests, so it can handle pushing shelves weighing several hundred kilograms without any problems.

Another issue is that supermarkets and other commercial establishments are most afraid of closing down due to renovations. If we use our flooring, even if one or two pieces are damaged, you can simply use a heat gun to blow on the damaged piece to pry it off and replace it with a new one, without affecting business operations at all.

Your Partner in Premium Glue Down Vinyl Flooring Solutions.

Flooring that Lasts. Partnerships that Grow

Your Trusted Manufacturer for High-Quality Glue down vinyl plank flooring —Reliable Supply, Competitive Pricing, and Tailored Solutions for Distributors, Wholesalers, and Global Importers