What’s composite cladding (composite siding)?

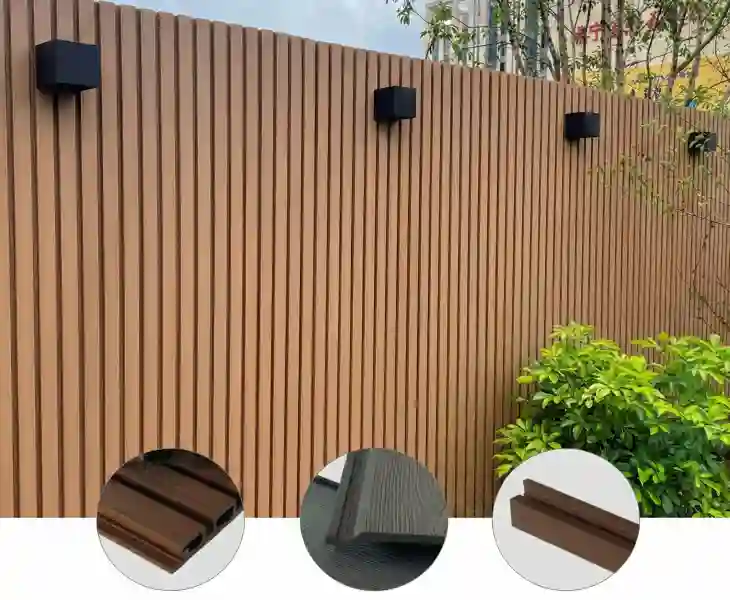

Green Covering Factory’s Composite Cladding also known as Composite siding or WPC cladding, which is kind of a synthetic wood siding, it’s a outdoor decorative materials that imitate the texture of wood, but composite siding is stronger and more eco-friendly than wood. Green Covering Factory’s composite siding can be used for facade exterior wall, composite ceiling, composite shed or composite planter and more.

Why Green Covering Factory’s composite cladding?

GreenCovering Factory’s composite siding (composite cladding) offers excellent stable properties as well as splitting resistance, fire resistance, weather durability, etc. Compared with other composite siding, GreenCovering WPC cladding has many features and advantages. GreenCovering is a perfect business partner for you as we only serve for business market with competitive prices and sustainable quality. Not all composite cladding & cladding are manufactured using the same process. Different raw materials, proportions, and manufacturing processes lead to variations in price. With the wide variety of panel types available on the market today, we ensure that our WPC cladding you purchase not only meets standards but is also of superior quality. Customer satisfaction and repeat business are more important than ever.

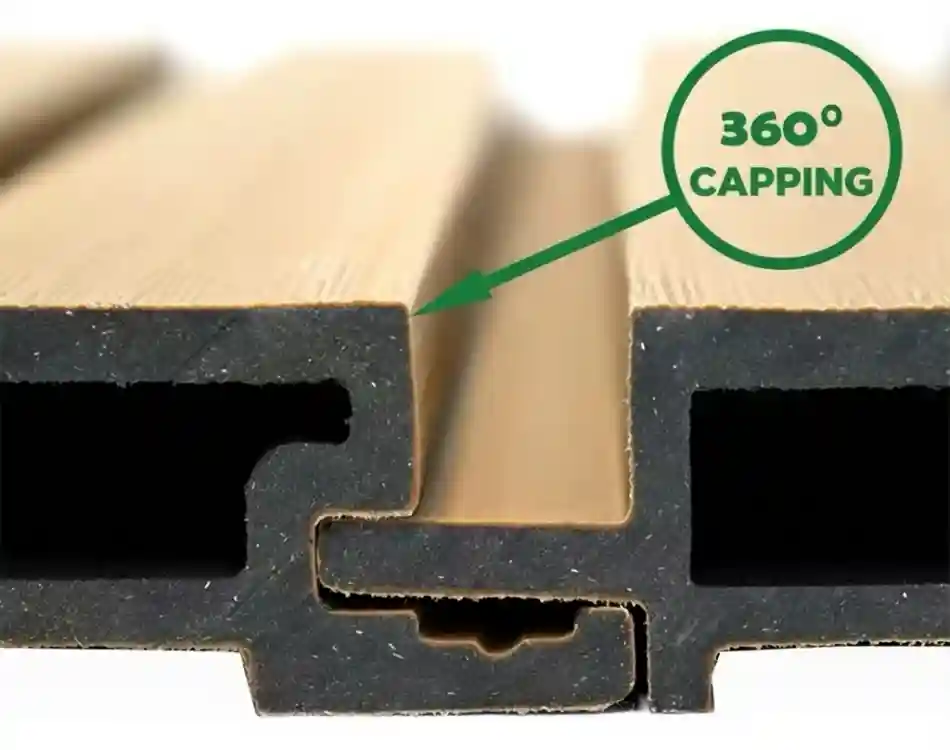

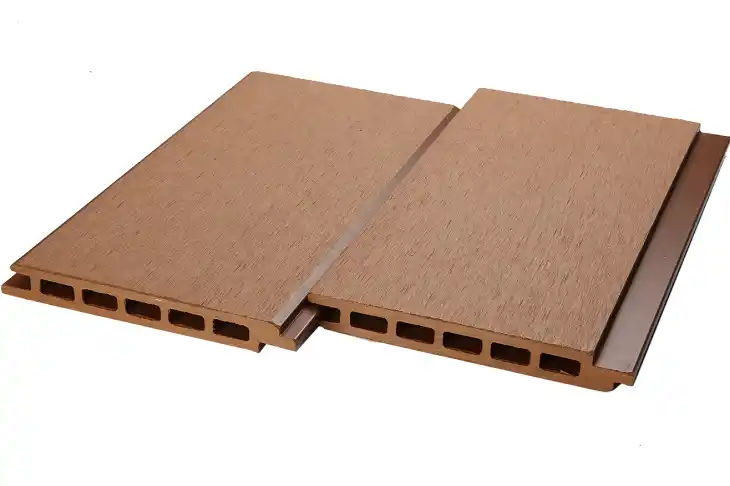

What is co-extruded composite cladding (composite siding)?

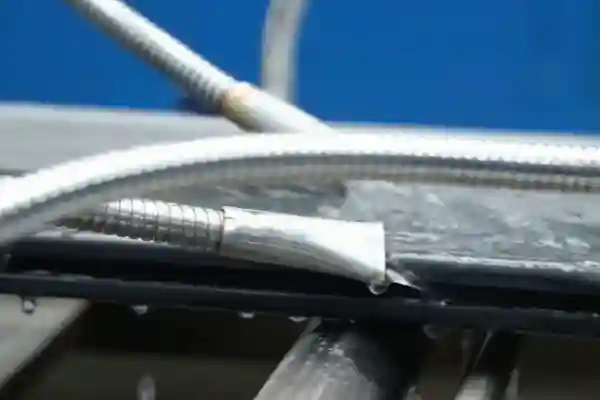

Our new generation composite cladding & siding are completely surrounded by a protective layer. We call it co-extruded composite siding, the surface layer is made of HDPE to prevent moisture penetration. Our cmoposite cladding and composite siding feature both a waterproof surface and an inner core. In coastal areas or during prolonged heavy rainfall, our advanced material will not absorb water and swell, preventing mold and cracking, thus saving on maintenance costs. It offers dimensional stability and does not change with temperature fluctuations. It forms an impermeable protective layer, providing scratch resistance, stain resistance, and fade resistance

OUR PRODUCT

Professional composite cladding & siding supplier in China

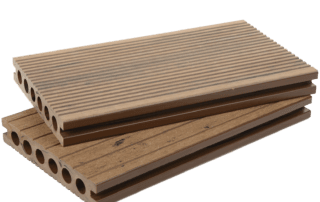

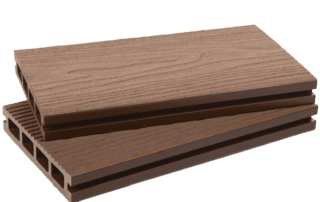

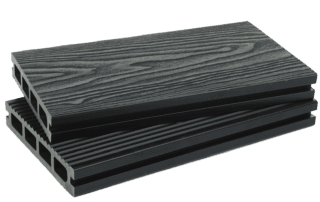

Green Covering Factory offer a variety of styles and colors, saving you the need to pay expensive mold fees.

GreenCovering Composite Siding Project Solutions

GreenCovering Factory has extensive experience in WPC cladding manufacturing and export, with our composite cladding products sold to over 80 countries. Due to varying climate conditions in different countries, the material composition of our products needs to be adjusted accordingly. For example, in Australia, we have developed a special formula specifically for the country’s harsh climate. Similarly, for coastal regions of Thailand, we ensure that our composite cladding&siding perform exceptionally well in terms of performance, lifespan, and durability, whether in environments with intense sunlight and high UV radiation or in humid and cold conditions.

GreenCovering is a leading manufacturer of composite siding in China

To produce high-quality exterior cladding, every step is crucial. Our raw materials are free of toxins and fossil fuel chemicals, manufactured using the highest quality recycled wood and plastic materials, and exhibit excellent resistance to temperature cycles and freeze-thaw conditions. Our factory covers 50 acres and has 80 production lines, making us a leading composite siding supplier in China. We have obtained over 90 patents and intellectual property rights and have passed various product certifications, such as ISO9001, FSI, CE, REACH, ASTM, etc.

1.Raw Material Testing (IQC): Every batch of raw materials arriving at our factory must be tested by our laboratory to ensure that the raw materials meet the requirements before production can begin.

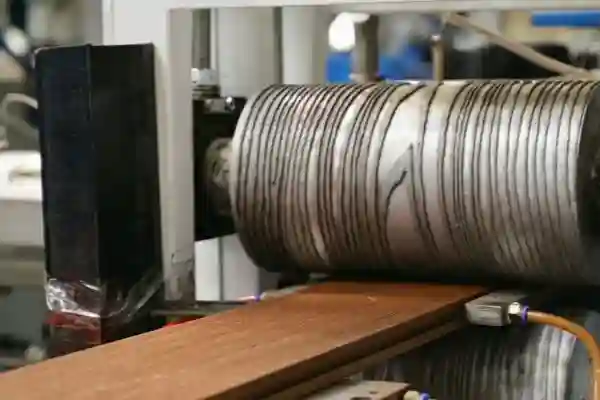

2.The wood powder, HDPE, and other raw materials are thoroughly mixed together, and then subjected to high temperature and shear force to transform them into stable wood-plastic granules

3. Our wood-plastic granules are then heated to a high temperature of 180 to 200 degrees Celsius, becoming a viscous fluid. Using a mold, along with cold water and vacuum suction, the composite cladding material is rapidly cooled and shaped, ensuring precise dimensions.

4. Initial product inspection (IPQC) of the first batch of composite cladding produced: we will check for surface impurities, cracks, dimensions, water absorption rate, expansion rate, etc., and monitoring temperature changes every hour.

5. Surface treatment: Our composite siding surface is treated with sanding, brushing, or embossing techniques to make it more closely resemble the feel of natural wood.

6. Cutting and packaging: according to the dimensions requested by our customer, the machine performs automatic cutting.

7. Inspection (FQC): We will check the siding’s dimensions, thickness, color, surface treatment ect.

8. Packaging and shipping (OQC): Check that the pallets are stable, and perform a final check of the cladding’s color, size, etc,to ensure that our composite siding arrives safely and on time.

The first generation of composite siding has a water absorption rate of 0.5%-1.5%, making it a viable option for large projects with limited budgets. It’s also suitable for those who appreciate the natural weathering and “aged” look of wood.However, the heavy metal-free pigments we use, even though they are a first-generation product, can guarantee that after the initial 2-3 months of normal fading, the color will last for 5-10 years.

The second generation of wood-plastic composite(co-extruded composite cladding) has a water absorption rate of 0.2%. If it’s for a villa or an area near a swimming pool where it’s prone to water exposure and oil stains, we recommend choosing the co-extruded wood-plastic composite, as it’s easier to clean. Even after being exposed to rain outdoors for 10 years, the inside of the boards remains dry and will not mold.

physical and chemical properties of our composite claading

We value every customer and every order; quality is the best guarantee we can offer our customers

| Items | Test Results | Test Methods |

|---|---|---|

| Density | 1.33g/cm3 | ASTM D792-00 |

| Moisture Content | 0.2% | ASTM D7031-11 Section 5.15 |

| Screw withdrawal test | 3353N | ASTM D7032-17 Section 5.5 ASTM D1761-12 |

| Impact Resistance | >133J | ASTM D4495-16 |

| Specific Gravity | 1.31 | ASTM D7031-11 Section 5.14 ASTM D792-13 Method A |

| Shore Hardness | D/70/1 | ASTM D2240-15 |

| Mouldproof level | 0[1] | ASTM G 21-15 |

| Formaldehyde Emission | 0.02ppm[2] | ASTM D6007 -14 |

| Soluble heavy metal | ND[3] | ASTM F963- 16(Clause 8.3) |

| Fire-Proof Level | Bf1 | EN ISO 9239-1:2010 EN ISO 11925-2:2010+AC:2011 |

What our customers are saying

We selected the composite cladding from Green Covering Factory for a beachfront villa project. After two years of intense UV and salt spray, the color retention is phenomenal—no fading or warping whatsoever. I must mention Coco, who was instrumental in recommending the right technical specifications for this harsh environment. The project still looks as fresh as day one, significantly increasing the property value. It’s a premium solution for any high-end exterior.

As a contractor, installation speed is my top priority. The interlocking system on these panels from Green Covering Factory is exceptionally well-engineered, allowing us to cover large wall areas 30% faster than traditional wood. Throughout the procurement process, Cathy provided professional support, from sending timely samples to coordinating the complex shipping schedule. The hidden fastener system provides a clean finish that our architects love. Truly a top-tier supplier.

What impressed me most was the authentic wood-grain texture; it avoids the ‘plastic’ look common in other composites. Green Covering Factory has mastered the balance between form and function. Coco was incredibly helpful in providing the LEED certification documents and fire-rated test reports my clients required. Knowing the cladding is made from recycled fibers makes it an easy sell for our eco-conscious projects. We look forward to many more collaborations.

Composite wall cladding factory

Composite cladding is the optimal solution for exterior wall design, The shield provides the composite exterior wall panels with matchless colors and textures, with high stain resistance and UV resistance, long service life, and ultra-low maintenance costs.

Composite siding and wall panels can be used for at least 15 years, any colors you want we can make it for you. loading with pallets and into containers can be mixed with many different designs.

OUR PRODUCT

Some about composite cladding you may interested

1.How much is composite siding&cladding?

The composite siding price is normally based on your project details and quantity. If you order the siding or cladding in big amounts, the price will be lower than samll order

2.How to install composite siding?

Before composite siding installation, check that the wall surface is flat. Install furring strips/joists, maintaining a consistent spacing, generally recommended at 12 inches. Install starter clips/strips and composite trims. Put the bottom of the first composite cladding into the starter clips, then place the second panel, aligning its groove with the clip on the first panel. Leave a minimum 3mm expansion gap between each composite siding, depending on the ambient temperature

3.How long does composite siding last?

Our composite siding has a design life of over 25 years, and during those 25 years, you won’t need to repaint or perform any maintenance.

4.Can you use composite trim as siding?

This is not recommended because composite trim does not have the tongue and groove design typically found in composite siding. If installed horizontally, rainwater can easily seep through the gaps, leading to mold growth inside the wall. Additionally, trim can only be installed with screws, and composite materials will expand and contract with temperature changes. The fixed screws will restrict this movement, causing the panels to buckle

5.Do you have vertical composite cladding and horizontal composite cladding?

Generally, vertical composite cladding and horizontal composite cladding are the same, only the installation direction differs.